Industry

Keep automotive lines running smoothly with feeders that reliably sort and orient small parts.

Check Out our complete line of Feeding & Conveying Solutions

Reliable Part Orientation for Automotive Assembly

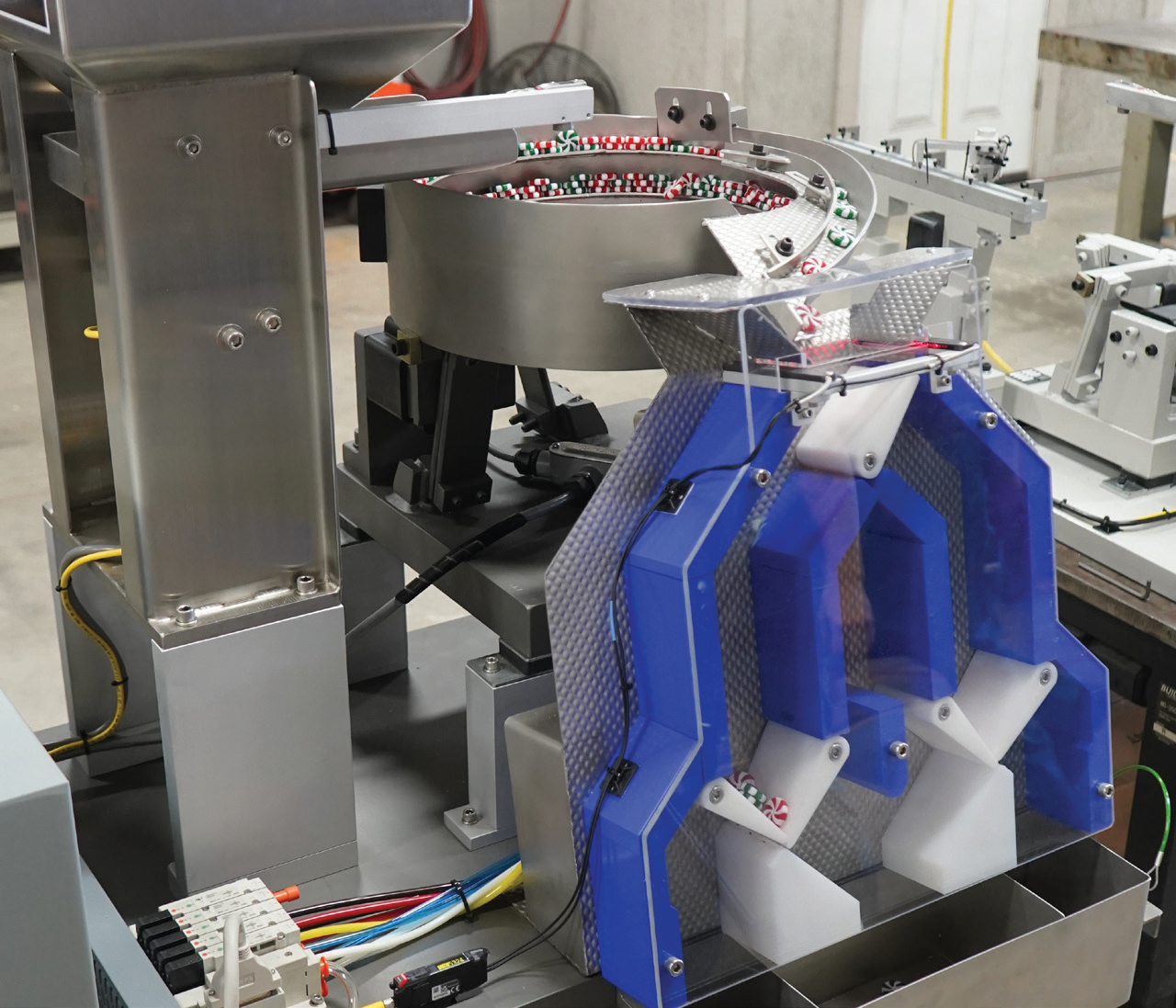

Automotive applications often involve high part volumes and tight cycle times. Hoosier Feeder systems are used to handle parts like clips, pins, fasteners, bolts, retainers, and other components that need to be properly oriented before assembly. Our feeder bowls are designed to deliver reliable part presentation, helping reduce manual handling and keep automated lines running smoothly.

Supporting Flow with Conveyors and Counting Systems

Beyond feeder bowls, Hoosier Feeder supports automotive applications with solutions like conveyor system, our clip placement system, and vibratory feeders with integrated counting. These tools help manage product flow and maintain consistent throughput. Designed to fit into a range of setups, they keep parts moving steadily through each stage of the production process.

Conveyors

SOLUTIONS

We build custom systems that feed, orient, and move parts efficiently—built to match each application and help our customers hit their automation goals.