No two production lines are the same.

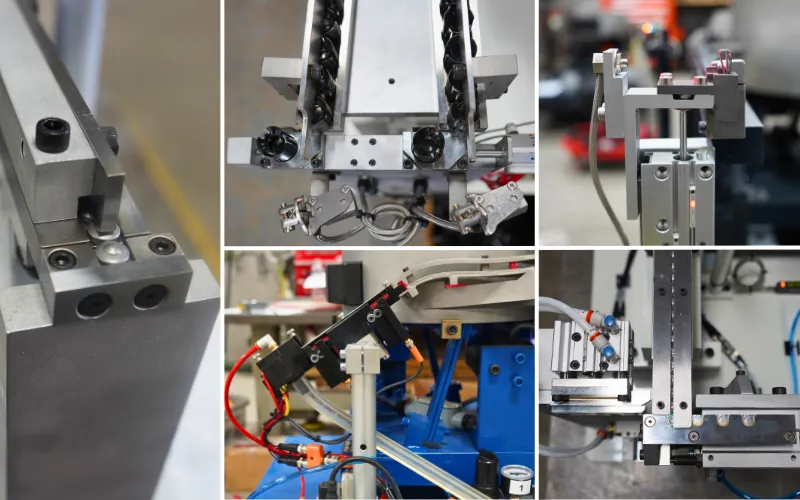

That’s why custom escapements and mechanisms are essential to keeping manufacturing operations running smoothly. At Hoosier Feeder, we design and build custom mechanisms, escapements, and nests that integrate seamlessly with your parts feeding system, improving precision, speed, and overall reliability.

Understanding Escapements, Mechanisms & Nests

In automated feeding systems, escapements, mechanisms, and nests work at the discharge point to deliver parts to the right spot, in the right orientation, and at the right time. These engineered components transform feeders into complete automation solutions tailored to your specific application.

Escapements: Controlled Part Isolation and Release

Escapements are mechanical devices placed at the end of the feeder discharge to isolate and release parts in a controlled manner. They separate one component at a time or in a specific sequence from the bulk supply, preventing jams and creating consistent spacing between parts. Escapements come in various forms, including finger mechanisms, blow feeds, and counting devices, all designed to control part release with precision. These solutions are critical for applications requiring consistent part timing and synchronization with robotic or packaging automation.

Mechanisms: Precision Part Movement & Transfer

Mechanisms provide the motion needed to transfer, reorient, or guide parts from the feeder to downstream equipment. From gravity-fed transfers to powered shuttle systems, these components streamline part handling and create seamless integration with assembly stations, inspection systems, and packaging equipment. They reduce cycle times, prevent jams, and position parts correctly for pick-and-place operations.

Dead Nests: Repeatable Positioning for Robotic Automation

Often referred to as “parking spots” for parts, dead nests are precision fixtures that provide a stable, repeatable location where robotic automation and pick-and-place systems can reliably retrieve components. When exact positioning is critical, nests eliminate variability in part placement, enabling faster cycle times, reducing failed picks, and maintaining consistent production quality across consumer goods, medical devices, automotive components, and precision assembly operations.

Together, these end-of-line solutions reduce downtime, improve throughput, and make integration between feeding systems and downstream automation more efficient and reliable.

Integration & Customization for Every Production Line

Our engineers don’t believe in one-size-fits-all solutions. Each production environment is unique, which is why we evaluate every application based on:

- Production rates – matching throughput requirements to feeder capacity and tooling design

- Part configuration – accommodating geometry, weight, material characteristics, and orientation requirements

- Downstream equipment requirements – ensuring seamless handoffs to robots, inspection systems, packaging equipment, and assembly stations

This application-focused approach allows us to design escapements and mechanisms that reduce downtime, extend the life of feeder systems, and increase overall throughput without compromising on precision or reliability.

Common Custom Tooling Solutions

At Hoosier Feeder, we offer a wide range of custom end-of-line solutions that integrate with vibratory feeders, centrifugal feeders, and orienting conveyors:

- Dead Nests – secure and hold parts for robotic pickup with repeatable positioning

- Gravity Tracks – reliable part transfer using gravity for consistent flow between operations

- Blow Feeds – high-speed delivery of lightweight parts using compressed air

- C Tracks – controlled part movement in compact footprints for space-constrained applications

- Isolation Cross Shuttles – separate and direct parts across production lines or between systems

- Custom Escapements – including finger mechanisms, rotary gates, and counting devices for controlled single-part release

- And More – custom tooling solutions engineered for your unique application

Each solution is designed specifically for your parts and processes, ensuring optimal performance from day one.

Ready to Optimize Your Parts Feeding System?

Whether you’re working in food processing, packaging, assembly automation, or consumer goods manufacturing, our team can design the right escapement and mechanism solution for your parts and processes.

From initial consultation through final installation, we work closely with you to understand your challenges and engineer solutions that deliver measurable improvements in efficiency, reliability, and throughput.

Contact Hoosier Feeder today to discuss how custom escapements and mechanisms can optimize your production line and support your automation goals.