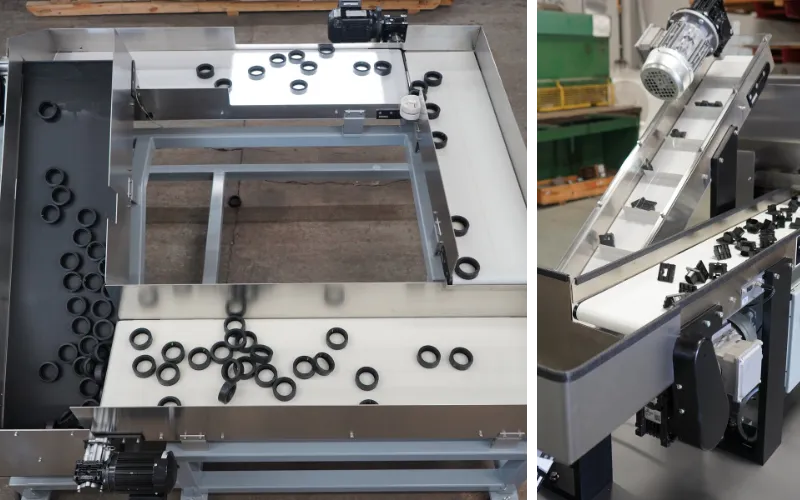

Simplifying Part Feeding for Automation

Flex feeders are an adaptable feeding solution designed to handle a wide variety of part shapes and sizes. Unlike traditional vibratory or centrifugal feeders that require custom tooling for each part, flex feeders use a vision-guided robotic system to pick and place parts in the correct orientation.

Why Choose a Flex Feeder?

- Scalable – Easily handles different product sizes

- Quick Changeovers – Capable of handling mutiple product types on one system

- Increased Production – Rates up to 30 parts per minute in two or four lane configurations

- Compact Design – Customizable solution in a compact footprint

- Inspection Capabilities – with integrated backlit

Let’s Chat

Flex feeders are a great solution for streamlining operations while maintaining flexibility in their production lines.

Want to see if a flex feeder fits your application? Let’s talk!